In The World Of Woodworking, The Debate Between Corded Power Tools And Battery-Powered Tools Has Been Ongoing For Years. Each Type Has Its Own Set Of Advantages And Limitations, And Choosing The Right One Depends On Your Specific Woodworking Needs And Preferences. In This Blog Post, We’ll Dive Into The Pros And Cons Of Both Corded And Battery Power Tools, Helping You Make An Informed Decision For Your Woodworking Projects.

1) Butt Joint

A butt joint is the simplest and most basic type of joint, where two pieces of wood are joined together at their ends, forming a right angle. This joint is quick to make but is not very strong on its own. It’s often used for simple and non-structural projects where strength isn’t a primary concern, such as attaching a back panel to a cabinet.

2) Miter Joint

A miter joint is created by cutting two pieces of wood at an angle, typically 45 degrees, and joining them to form a corner. This joint is commonly used for decorative purposes, such as framing artwork, mirrors, or creating beveled corners on trim work.

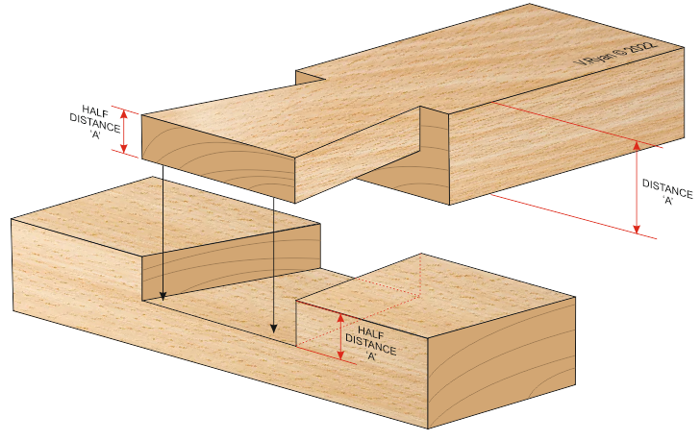

3) Half Lap Joint

he half-lap joint involves removing half the thickness of each piece of wood to create an overlapping joint. It’s known for its strength and is often used in making grids for cabinet doors or in creating sturdy frames.

4) Dovetail Joint

Dovetail joints are renowned for their strength and visual appeal. They consist of pins and tails that interlock at a 90-degree angle, resembling a dove’s tail, hence the name. Dovetail joints are used in high-quality furniture construction, drawers, and boxes, where both strength and aesthetics are crucial.

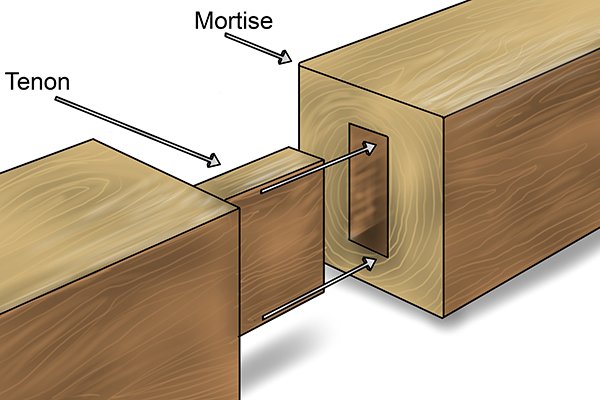

5) Mortise And Tenon Joint

The mortise and tenon joint is one of the most versatile and strong woodworking joints. It consists of a mortise (a hole or slot) in one piece of wood and a tenon (a projecting tongue) on the other piece that fits snugly into the mortise. This joint is commonly used in table and chair construction, door frames, and other furniture pieces.

6) Biscuit Joint

Biscuit joints are simple and effective, using oval-shaped wooden biscuits and glue to align and secure two pieces of wood. They are commonly used for edge-to-edge joining, such as joining tabletop boards together, and for aligning parts during glue-up.

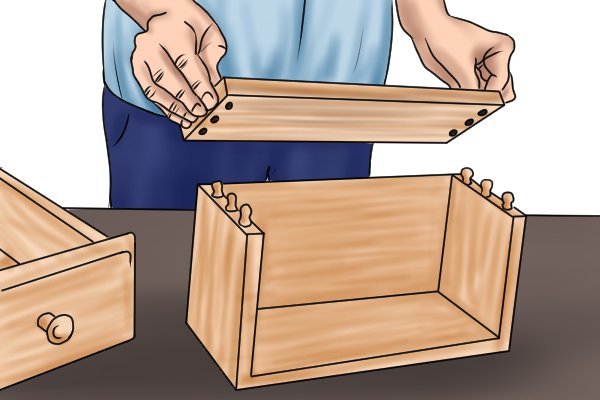

7) Dowel Joint

Dowel joints use wooden dowels inserted into precisely drilled holes to align and strengthen the connection between two pieces of wood. They are commonly used in assembling furniture, cabinets, and frames, providing a clean and hidden fastening method.

8) Dado And Rabbet

Dado joints involve cutting a groove across the grain of one piece of wood to accept the end of another piece, creating a strong and flush connection. Rabbet joints are similar but involve cutting a groove along the edge of one piece to accept the end of another. These joints are widely used in cabinet and bookshelf construction.

9) Pocket Hole Joinery

Pocket hole joinery is a woodworking technique used to create strong and hidden joints between two pieces of wood. It involves drilling an angled hole (the “pocket hole”) into one workpiece and then joining it to another workpiece using screws. The result is a strong, sturdy, and concealed connection. Pocket hole joinery is often used in cabinetmaking, furniture construction, and various woodworking projects. A pocket hole jig is normally used to make the holes used in this kind of joinery.

Choosing The Right Joint To Use

By understanding these woodworking joints and their respective use cases, you’ll have the knowledge and skills to choose the right joint for your woodworking projects, whether you’re aiming for strength, aesthetics, or both. Each joint has its unique advantages and applications, allowing you to craft projects that are not only functional but also beautifully constructed.